Metal & Steel

Home Appliances Material IndustryMulti-Color Silk Screen Printing AJU MCM. Co., Ltd.

As the only processing center, MCT provides products that meet the needs of our customers through best quality and swift delivery.

- - CCL Line No. 1(used also for Coil & In-Line Sheet)

- - Slitter Line No. 4

- - Shear Line No. 5

- Processing Service Line

-

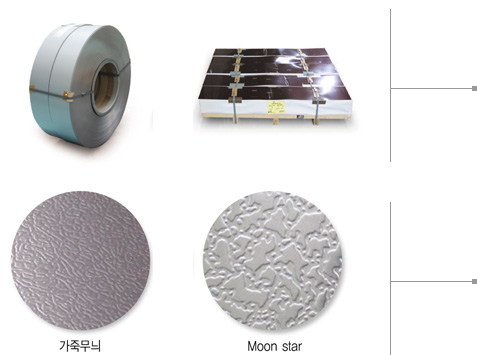

Coil & Sheet Products

Coil & Sheet Products

Accommodates various processing capabilities with the highest number of equipment- Processing line exclusive for high quality home appliances

- Sheet-to-sheet processing line that ensures a good quality of external appearance

- Total visual inspection for refrigerator door, TV back cover, etc.

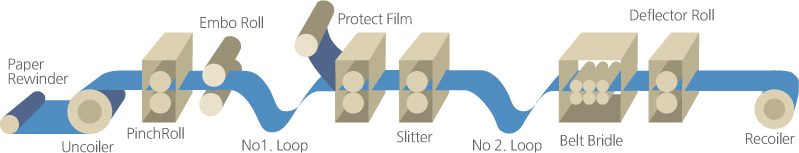

Emboss Products

Multi-use line for embossing coils- Coil or Sheet products

- Leather pattern, Moon star

- Color Line

-

COLOR PCM

COLOR PCM

Low-cost, high-quality; black textured resin PCM products- Superior processing ability, good hardness and chemical resistance

- Mainly used for home appliances that require good design

Clear Coating

Projects the elegant texture of metallic surfaces such as AL, STS, etc.- Hairline-textured, high-gloss AL PCM

- No. 4 hairline-textured high-clarity STS PCM

Laminating(VCM)

Laminating products such as laminating PVC, PET and thick film- General VCM products with high clarity, high gloss and multiple design

- Exclusive production of VCM that applied new technology, incl. horizontal hairline, ILM, etc.

- About Equipment

-

-

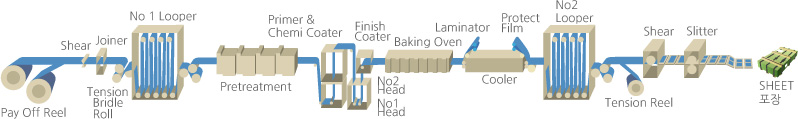

Compact color-coating and laminating equipment for audio/video appliances

- - Coating equipment: Produce beautiful colors through underground installment minimizing vibration

- - Laminating equipment: Quality equipment for high-quality home appliances

-

Equipment for primer & chemi

- - Developed low-bake primer and equipment(patent application)

- STS, AL PCM, AL VCM thin film laminating equipment

-

IN LINE

- - to be confirmed

- - to be confirmed

- - One-step production from coating, shearing to slitting; minimize poor quality

-

Compact color-coating and laminating equipment for audio/video appliances

- Manufacturing Process

- Features

-

- Product quality guaranteed by belt bridle and pad

- Quality standards in slitting guaranteed by attaching pascal control unit

- High quality guaranteed by slip sheet and protection film equipment

- Quality of thin & special material processing guaranteed by precision control (AL 0.2T)

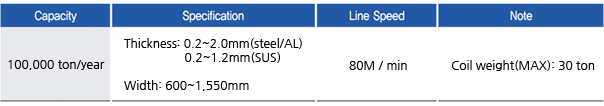

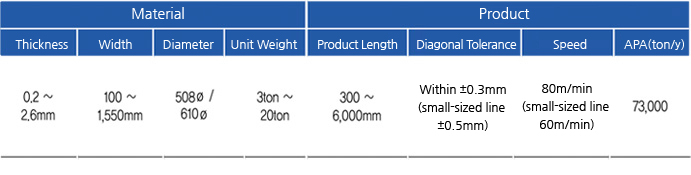

- Production Capacity

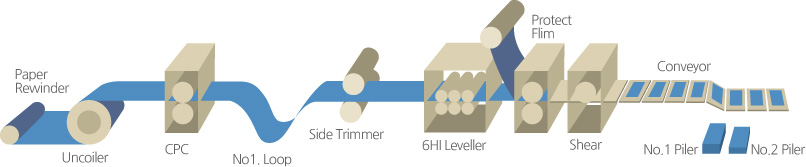

- Manufacturing Process

- Features

-

- Minimize diagonal tolerance and provide precise flatness by CPC system and 6-high leveler

- Minimize burr by installing drum shear system for the first time nationwide

- High quality guaranteed by slip sheet and protection film equipment

- Production Capacity

- Manufacturing Process